The way tobacco burns in a cigarette is one of the most important factors that define the smoking experience. Combustion affects flavor, aroma, burn rate, ash formation, and even the efficiency of nicotine delivery. For manufacturers, controlling combustion is essential for product consistency, quality assurance, and brand reputation.

This guide explores the key factors that influence tobacco combustion in cigarettes, from the properties of the leaf to the role of machinery and filter technology. By understanding these variables, manufacturers can fine-tune their processes to deliver the desired smoking characteristics while maintaining efficiency in production.

Combustion in cigarettes is a controlled burning process where heat, oxygen, and chemical composition work together. Ideally, a cigarette should burn evenly, without going out too quickly or producing an uneven ash.

The temperature during smoking ranges between 400°C to 900°C, depending on whether the cigarette is being actively puffed or left to smolder. This temperature range influences the release of nicotine, tar, and aromatic compounds, which shape the smoker’s sensory experience.

Different tobacco types—Virginia, Burley, and Oriental—burn differently:

The blend ratio of these tobaccos influences how evenly a cigarette burns and the smoothness of the smoke.

Thin, fine leaves burn faster, while thicker leaves with more cellulose burn slower. Manufacturers carefully balance these properties to ensure a cigarette neither burns too quickly nor extinguishes prematurely.

Moisture levels are critical. Overly dry tobacco burns too hot and fast, leading to harsh smoke. Excessively moist tobacco struggles to stay lit. Advanced tobacco machinery helps regulate moisture during processing to achieve consistency.

Processing tobacco before it reaches cigarette machines is a decisive stage in combustion performance.

Uniform cutting and blending are made possible by precision machinery, ensuring each cigarette maintains consistent burning qualities.

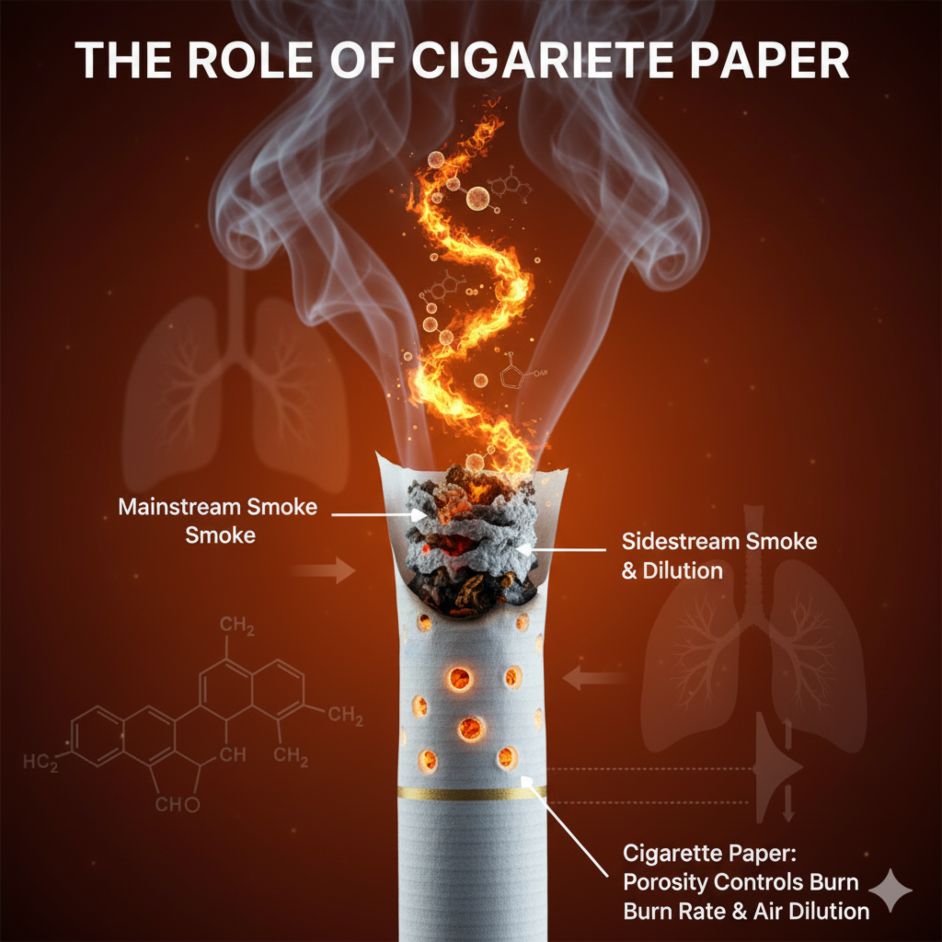

Paper is not just a wrapper; it’s a combustion regulator. Manufacturers use papers with specific porosity levels to control airflow:

Burn additives in the paper can also ensure that cigarettes extinguish when left unattended, improving safety and meeting regulatory requirements.

Filters have a significant impact on combustion by altering airflow and smoke delivery.

Modern factories rely on cigarette filter making machines to produce filters of varying types, including:

The resistance to draw created by the filter affects how a cigarette burns. A tighter filter can slow combustion, while a looser filter allows faster airflow and quicker burning.

Advanced machinery ensures that every cigarette produced has a consistent combustion profile.

Consistency at the machinery stage ensures that every cigarette within a pack burns the same way, building consumer trust in the brand.

Manufacturers sometimes use additives to regulate burning properties:

These are carefully controlled to meet regulatory requirements while enhancing smoking experience.

Even after production, combustion quality can be affected by external factors:

This is why proper storage and logistics are vital in protecting brand quality during distribution, especially in markets like cigarette brands in Dubai where product freshness is critical.

Modern cigarette production facilities are increasingly focused on sustainability. Efforts include reducing chemical additives, using eco-friendly papers, and recycling production by-products. Machinery upgrades also help cut energy use, ensuring both efficiency and environmental responsibility.

Q1. Why do some cigarettes burn faster than others?

Burn rate depends on tobacco cut size, moisture content, paper porosity, and filter design. Precision machinery ensures consistency in these factors.

Q2. How does moisture control affect combustion?

Proper moisture levels prevent harsh smoke and ensure steady burning. This is managed by specialized tobacco machinery.

Q3. Can filters change how tobacco burns?

Yes. Filters regulate airflow, which impacts how quickly or slowly the cigarette burns. Modern cigarette filter making machines produce a variety of filter types to control this.

Q4. How do cigarette brands maintain consistent combustion?

Consistency is achieved by using high-quality blends, precision cigarette making machines, and strict quality control at every stage.

Tobacco combustion in cigarettes is influenced by multiple factors—leaf properties, processing methods, paper porosity, filters, and even external storage conditions. For manufacturers, controlling these variables ensures not only a consistent smoking experience but also compliance with safety and quality standards.

With advanced tobacco machinery, state-of-the-art cigarette making machines, and precise cigarette filter making machines, modern factories can fine-tune every detail of combustion. This combination of technology, expertise, and quality control helps global and regional players, such as cigarette brands in Dubai, deliver premium products to consumers worldwide.

We specialize in the provision of Tobacco Machinery. Our expertise encompasses not only the trading of machinery but also extends to being a dedicated supplier. This specialization is enriched by our comprehensive solutions tailored for emerging Cigarette Companies. What sets us apart is our ability to offer firsthand insights through our active Cigarette Manufacturing operation in the UAE.