Cigarette manufacturing machines are a complex process that requires precision, speed, and efficiency. In an industry where consistency and quality are paramount, the integration of advanced automation and control systems is essential. One such innovation that has significantly impacted cigarette manufacturing is the use of Lenze servo drives in the Molins Mark 9 cigarette making machine. This blog post will explore the intricacies of cigarette manufacturing, the specifications of the Mark 9 machine, and the pivotal role of Lenze servo drives in enhancing the machine’s performance.

Cigarette manufacturing has come a long way from manual rolling techniques to highly automated processes. Modern cigarette machines are marvels of engineering, capable of producing thousands of cigarettes per minute with remarkable consistency. These machines incorporate various components, each playing a crucial role in the manufacturing process. From cutting and blending tobacco to wrapping and packaging cigarettes, every step is meticulously controlled to ensure product quality.

Servo drives are integral components in modern automation systems, offering precise control, synchronization, and energy efficiency. Let’s explore the key features and benefits of Lenze servo drives in the context of cigarette manufacturing. ( View Cigarette Machinery Spare Parts )

In cigarette manufacturing, even minor variations can impact product quality. Lenze servo drives provide precise control over the machine’s movements, ensuring that each component operates accurately and consistently. This precision is essential for maintaining the high standards of quality expected in the tobacco industry.

The synchronization of various machine components is crucial to prevent misalignment and reduce the risk of jams or malfunctions. Lenze servo drives excel in this regard, helping to synchronize the different parts of the cigarette making machine. This seamless operation enhances overall efficiency and minimizes downtime.

Different stages of the cigarette manufacturing process require varying speeds. Lenze servo drives enable precise speed regulation, allowing the machine to operate at optimal speeds for each stage. This capability helps maintain high production rates while ensuring that the quality of the final product remains uncompromised.

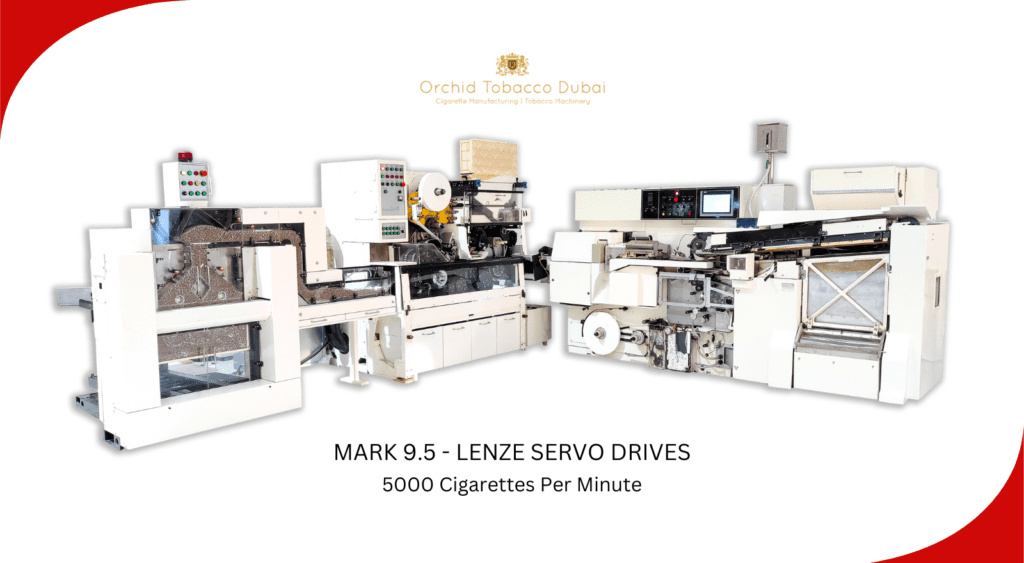

The Molins Mark 9 cigarette making machine is a testament to engineering excellence in the tobacco industry. Renowned for its high production capacity and precision, the Mark 9 is equipped with advanced features that make it a preferred choice for manufacturers worldwide. Let’s take a closer look at its specifications:

The Mark 9 boasts an impressive production capacity, capable of producing up to 3500 cigarettes per minute (cpm) for regular diameter cigarettes and 3200 cpm for slim and super slim variants. This high-speed production capability ensures that manufacturers can meet market demand efficiently. ( View Complete Tobacco Machinery)

The machine accommodates a wide range of cigarette circumferences, from 17mm to 28.3mm, and supports filter and tobacco rod lengths ranging from 65mm to 110mm. This versatility allows manufacturers to produce various cigarette types without extensive reconfiguration. ( Also Check Mark 8 Cigarette Making Machine )

Equipped with a SIEMENS PLC control system, the Mark 9 ensures precise and reliable control over the entire manufacturing process. The PLC system enables seamless integration of various machine components, enhancing overall efficiency and reducing downtime.

To maintain consistency in cigarette weight, the Mark 9 employs a microwave-based weight control system. This technology ensures that each cigarette contains the exact amount of tobacco, preventing variations in product quality.

At the heart of the Mark 9’s precision and control is the Lenze servo system. This advanced system plays a pivotal role in synchronizing the machine’s movements, regulating speed, and ensuring energy efficiency.

The Mark 9 machine comprises several key units, including the MK-9.5 cigarette maker, MAX-S filter assembler, and HCF80 auto tray filler. These units work in harmony to streamline the manufacturing process and enhance productivity.

The machine’s power requirements are substantial, with the MK-9.5 unit consuming 35KW, the MAX-S unit consuming 20KW, and the HCF80 unit consuming 15KW. Despite its high power consumption, the Mark 9’s efficient design ensures optimal energy utilization. The total weight of the machine is approximately 8,600 KG, reflecting its robust construction.

Servo drives play a critical role in cigarette manufacturing, offering numerous advantages that enhance the overall performance of the machinery. Let’s examine the importance of servo drives in more detail. ( Check Tobacco Machinery Spare Parts )

Energy costs can be significant in high-speed manufacturing environments. Lenze servo drives provide efficient power management, reducing energy consumption and lowering operational costs. This energy efficiency is particularly beneficial for manufacturers looking to optimize their production processes. Don’t miss our Cigarette Packing Machines

Manufacturers often need to produce a variety of cigarette types and switch between different production runs. Lenze servo drives offer the flexibility to accommodate diverse production requirements. They can be programmed and adjusted to meet the specific needs of different products, making them ideal for manufacturers with varied production portfolios.

The integration of Lenze servo drives in the Molins Mark 9 cigarette making machine represents a significant advancement in cigarette manufacturing technology. By providing precise control, synchronization, speed regulation, and energy efficiency, these servo drives enhance the machine’s performance and ensure consistent product quality.

For industrial engineers, automation enthusiasts, and manufacturing professionals, understanding the role of servo drives in cigarette machinery is essential for optimizing production processes and achieving competitive advantages.

We specialize in the provision of Tobacco Machinery. Our expertise encompasses not only the trading of machinery but also extends to being a dedicated supplier. This specialization is enriched by our comprehensive solutions tailored for emerging Cigarette Companies. What sets us apart is our ability to offer firsthand insights through our active Cigarette Manufacturing operation in the UAE.