In the intricate world of cigarette manufacturing machines, the importance of precision and efficiency cannot be overstated. One of the pivotal components in this industry is the tobacco cutting machine, an essential tool that ensures the quality and consistency of every cigarette produced.

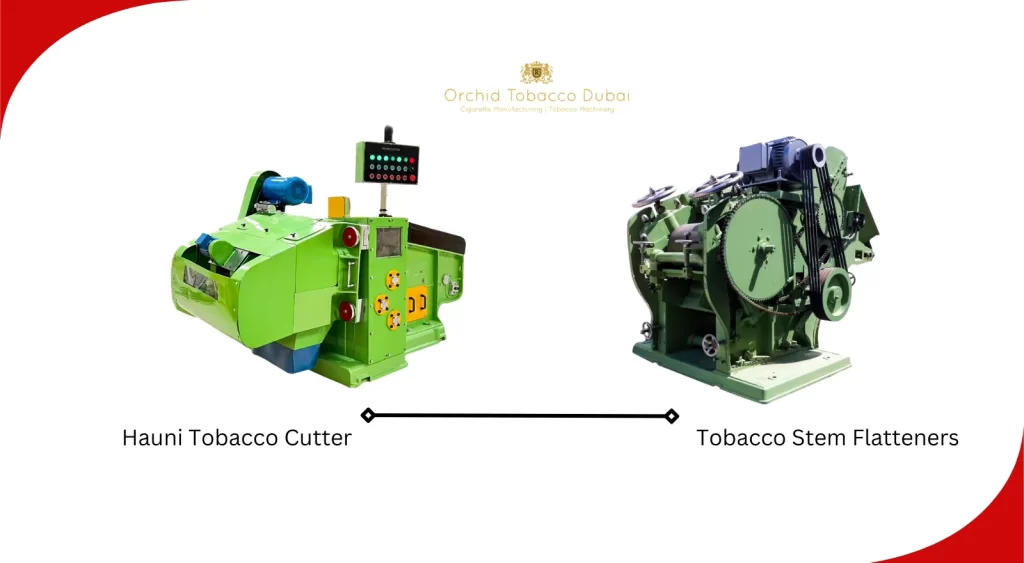

This blog post aims to provide an in-depth look at these marvels of engineering, focusing on their functionality, specific models like the Hauni Tobacco Cutter KT-400, and their role in cigarette production. Whether you’re a tobacco industry professional, a machinery enthusiast, or a cigarette factory owner, this comprehensive guide will offer valuable insights into the world of tobacco cutting machines. ( Do you know about Tobacco Stem Flattener? )

Tobacco cutting machines are specialized pieces of equipment designed to process raw tobacco leaves into uniform strips suitable for cigarette production. These machines are engineered to handle large volumes of tobacco with precision, ensuring each cut meets the exact specifications required for high-quality cigarettes. ( View Our Tobacco Machinery )

The core function of these machines is to cut the tobacco leaves into thin, uniform shreds that can be easily blended and packed into cigarettes.

Industrial tobacco cutting machines are equipped with advanced features that allow for precise control over the cut size and consistency.

They utilize sharp knives and sophisticated mechanisms to slice through the tobacco leaves, maintaining the integrity of the fibers and ensuring minimal wastage. These machines are a testament to the advancements in technology within the tobacco industry, combining high-speed performance with meticulous accuracy.( View Our Cigarette Packing Machines )

Among the various models available, the Hauni Tobacco Cutter KT-400 stands out for its exceptional performance and reliability. This model is widely used in cigarette factories around the world, known for its ability to produce consistent and high-quality cuts of tobacco.

The KT-400 model from Hauni is a state-of-the-art tobacco cutting machine designed for maximum efficiency. It features a robust build and cutting-edge technology that makes it a staple in many cigarette production facilities. ( Check Cigarette wrapping Machines )

The KT-400 is equipped with five precision knives that ensure each cut of tobacco is uniform and consistent. These knives are engineered to maintain their sharpness over extended periods, reducing downtime and maintenance costs.

One of the standout features of the KT-400 is its use of pneumatic cylinders for jaw operation. These cylinders provide the force needed to cut through the tobacco leaves with ease, ensuring smooth and efficient operation.

The KT-400 utilizes a PLC drive on a brass bend slat for regulating the cut size. This advanced drive mechanism allows for precise control over the cutting process, ensuring that each shred of tobacco meets the desired specifications.

The Hauni Tobacco Cutter KT-400 plays a crucial role in the cigarette production process. Its primary function is to cut the tobacco leaves into thin strips that can be easily blended and packed into cigarettes. The precision and consistency provided by the KT-400 ensure that each cigarette contains the perfect blend of tobacco, enhancing the smoking experience for consumers.

By automating the cutting process, the KT-400 significantly improves the efficiency of cigarette production. It can handle large volumes of tobacco with ease, reducing the time and labor required to process the raw leaves.

The precision knives and advanced drive mechanism of the KT-400 ensure that each cut of tobacco is uniform and consistent. This consistency is crucial for maintaining the quality of the cigarettes, ensuring that each one delivers the same smoking experience. ( Check Cigarette Filter Making Machines )

The durability and reliability of the KT-400 reduce maintenance costs and downtime, resulting in significant cost savings for cigarette manufacturers. The machine’s ability to produce consistent cuts also reduces wastage, further enhancing its cost-effectiveness.

In addition to cutting machines, the tobacco industry also utilizes devices known as tobacco stem flatteners. These machines are designed to flatten the stems of tobacco leaves, making them easier to process and blend with the shredded tobacco.

Tobacco stem flatteners are specifically designed to flatten the tough stems of tobacco leaves. This process is crucial for ensuring that the stems can be evenly blended with the shredded tobacco, resulting in a uniform product.

The primary outcome of using tobacco stem flatteners is the production of a more uniform blend of tobacco. By flattening the stems, these machines ensure that they can be evenly distributed throughout the shredded tobacco, enhancing the consistency of the final product.

Tobacco stem flatteners offer several benefits to cigarette manufacturers. By ensuring a uniform blend of tobacco, these machines improve the quality and consistency of the cigarettes. They also reduce wastage by making it easier to process the tough stems, enhancing the overall efficiency of the production process. ( Check Mark 8 Cigarette Making Machine )

Tobacco stem flatteners are an essential component of the cigarette production process. By flattening the stems, these machines make it easier to blend the tobacco, ensuring that each cigarette contains the perfect mix of shredded leaves and stems. This consistency enhances the smoking experience for consumers, making tobacco stem flatteners a valuable asset for cigarette manufacturers. ( Check Mark 9 cigarette making machine )

The use of tobacco stem flatteners ensures that each batch of tobacco is consistent in terms of texture and blend. This consistency is crucial for maintaining the quality of the cigarettes, ensuring that each one delivers the same smoking experience. By enhancing the uniformity of the tobacco blend, stem flatteners play a key role in the production of high-quality cigarettes.

In the world of cigarette manufacturing, the importance of precision and efficiency cannot be overstated. Tobacco cutting machines, such as the Hauni Tobacco Cutter KT-400, play a crucial role in ensuring the quality and consistency of every cigarette produced. ( View Cigarette Soft Cup Packing Machines )

These machines combine advanced technology with meticulous engineering to deliver precise cuts of tobacco, enhancing the overall efficiency and quality of the production process.

Tobacco stem flatteners further enhance the production process by ensuring a uniform blend of tobacco. By flattening the tough stems, these machines make it easier to process and blend the tobacco, resulting in a more consistent and high-quality product.

For tobacco industry professionals, machinery enthusiasts, and cigarette factory owners, understanding the role and functionality of these machines is essential for optimizing the production process and ensuring the highest quality of cigarettes. (View Our Cigarette machinery spare parts)

By leveraging the advanced technology of tobacco cutting machines and tobacco stem flatteners, manufacturers can enhance their efficiency, reduce costs, and deliver a superior product to consumers.

If you’re interested in learning more about the latest advancements in tobacco cutting machines and other essential equipment for cigarette production, consider reaching out to industry experts or exploring additional resources. ( View All Cigarette Manufacturing Machines )

By staying informed and adopting the latest technologies, you can position your business for success in the competitive world of cigarette manufacturing.

We specialize in the provision of Tobacco Machinery. Our expertise encompasses not only the trading of machinery but also extends to being a dedicated supplier. This specialization is enriched by our comprehensive solutions tailored for emerging Cigarette Companies. What sets us apart is our ability to offer firsthand insights through our active Cigarette Manufacturing operation in the UAE.