The tobacco industry, with its highly intricate and mechanized production process, relies heavily on the efficiency of its machinery. As the demand for cigarettes continues to grow globally, manufacturers are constantly exploring new ways to improve their production lines. A critical yet often overlooked aspect of this process is the role of spare parts in maintaining the performance of cigarette manufacturing machines. Spare parts are essential to ensure the smooth and uninterrupted operation of these machines, contributing directly to the quality, quantity, and efficiency of the final product.

Here we will explore the latest innovations in tobacco machinery spare parts and how they are revolutionizing the industry. Additionally, we will highlight our commitment to providing the best and most reliable spare parts for tobacco machinery, ensuring that manufacturers have access to a complete range of high-quality components for their machines.

Cigarette manufacturing involves multiple stages, from the preparation of tobacco leaves to the final packaging of cigarettes. Each stage requires sophisticated machines designed for high-speed, precision, and reliability. As with any complex machinery, the components that make up these machines are subject to wear and tear over time. This is where spare parts come into play.

Spare parts are crucial for maintaining the functionality of tobacco machinery. They help extend the lifespan of machines, reduce downtime, and prevent costly production disruptions. Without the availability of high-quality spare parts, manufacturers would face longer repair times and potential delays in production, negatively impacting their business operations.

In recent years, there has been significant innovation in the field of cigarette machinery spare parts. These advancements aim to address the challenges faced by manufacturers, including improving the durability, efficiency, and ease of maintenance of machine components. Here are some key innovations that are making waves in the industry:

One of the key innovations in cigarette machinery spare parts is the use of advanced materials that offer enhanced durability and resistance to wear. Traditional materials used for parts like gears, rollers, and conveyors were often prone to damage due to friction and continuous use. However, modern spare parts are now made from high-strength alloys, ceramics, and composite materials that can withstand the harsh conditions of tobacco processing.

These materials help reduce the frequency of part replacements, ultimately lowering the overall cost of maintenance. Furthermore, they ensure that the machines continue to operate at peak performance for longer periods, reducing the likelihood of unplanned downtimes.

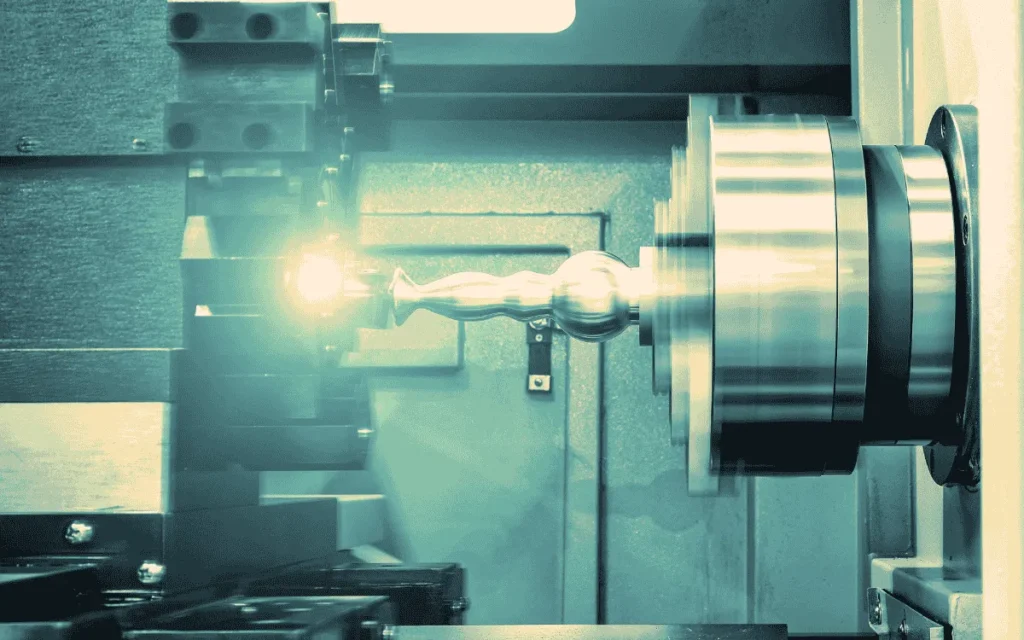

Another major innovation is the focus on precision engineering in the manufacturing of spare parts. With the demand for higher production speeds and consistent quality, cigarette machinery components must operate with extreme precision. Spare parts such as rollers, conveyors, and filter assembly parts are now manufactured to tighter tolerances, ensuring seamless operation and minimal friction.

Precision engineering also reduces the need for manual adjustments during the production process, improving overall efficiency and reducing the risk of human error. This innovation contributes directly to a more consistent and high-quality output of cigarettes.

The integration of the Internet of Things (IoT) into machinery is another exciting development that is making its way into the world of cigarette manufacturing spare parts. IoT-enabled spare parts come with sensors and smart features that allow for real-time monitoring and data collection.

For instance, sensors embedded in spare parts like motors and gears can monitor wear and tear, temperature, and vibration levels. This data can be transmitted to a central system, alerting manufacturers when a part is nearing the end of its useful life or requires maintenance. This predictive maintenance approach helps prevent costly downtime and ensures that the machinery is always running at optimal performance levels.

Sustainability is becoming increasingly important in the manufacturing sector, and the tobacco industry is no exception. Manufacturers are now focusing on developing eco-friendly spare parts that reduce environmental impact. These spare parts are made from recyclable materials and are designed to have a longer lifespan, reducing the need for frequent replacements.

Additionally, eco-friendly spare parts are often more energy-efficient, contributing to the overall reduction of the carbon footprint of cigarette production facilities. By choosing these sustainable parts, manufacturers can not only improve the environmental impact of their operations but also reduce waste and lower their overall operational costs.

Modular spare parts are another innovative development that provides flexibility to manufacturers. Rather than relying on custom-made parts for each machine, modular spare parts are designed to be interchangeable across different models and brands of cigarette machinery. This flexibility allows manufacturers to streamline their spare parts inventory and reduce the time spent on sourcing and replacing components.

Modular spare parts also make maintenance easier, as technicians can quickly replace faulty parts without having to wait for specialized components to be manufactured. This innovation significantly reduces machine downtime and keeps production lines running smoothly.

At Orchid Tobacco, we understand the importance of high-quality and reliable spare parts in the tobacco manufacturing process. As a leading manufacturer of tobacco machinery and spare parts, we are committed to providing our customers with a comprehensive range of products that meet the highest industry standards.

We pride ourselves on the quality and reliability of the spare parts we offer. Our components are designed to enhance the performance of cigarette machinery, ensuring that your production lines operate efficiently and without interruption. Whether you need parts for a cigarette-making machine, packing machine, or wrapping machine, Orchid Tobacco has you covered.

We offer a full range of spare parts for all types of cigarette machinery. Our inventory includes parts for:

All of our spare parts are manufactured to the highest quality standards, using advanced materials and precision engineering to ensure longevity, performance, and ease of maintenance.

As the tobacco industry continues to evolve, innovations in cigarette machinery spare parts are playing a crucial role in enhancing production efficiency, reducing costs, and improving the overall quality of the final product. At Orchid Tobacco, we are proud to offer a complete range of reliable and high-performance spare parts that support the smooth operation of your cigarette manufacturing machinery. Whether you are looking to upgrade your existing equipment or need high-quality replacement parts, Orchid Tobacco is your trusted partner in ensuring the longevity and efficiency of your production lines.

For more information about our spare parts and machinery, contact our team today.

We specialize in the provision of Tobacco Machinery. Our expertise encompasses not only the trading of machinery but also extends to being a dedicated supplier. This specialization is enriched by our comprehensive solutions tailored for emerging Cigarette Companies. What sets us apart is our ability to offer firsthand insights through our active Cigarette Manufacturing operation in the UAE.