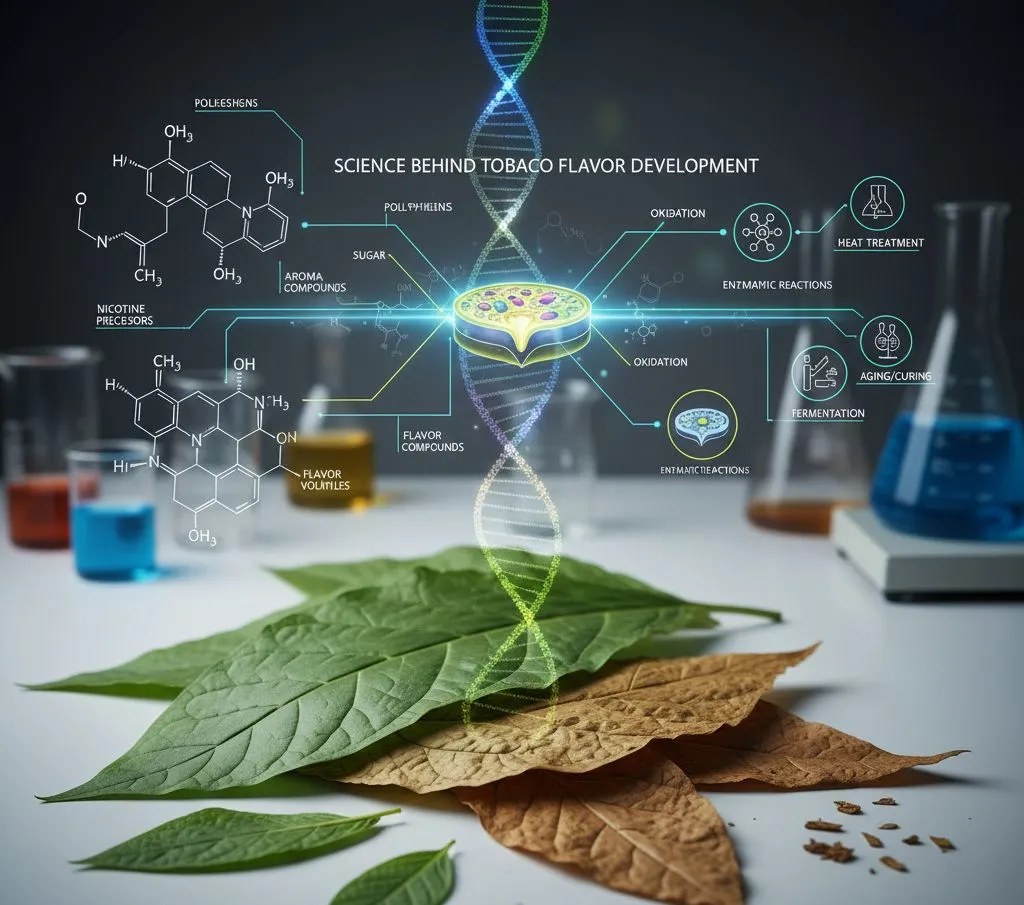

Flavor in tobacco is not just a function of the leaf or additives; it is the result of complex chemical, biochemical, and physical transformations. From the moment a tobacco leaf grows, through curing, aging, blending, and processing (cutting, casing, flavoring), multiple processes interact to produce the final aroma and taste encountered in a cigarette.

Flavor, Aroma, Taste — What Do We Mean?

Before we go chemical, we need to clarify:

- Taste refers to the basic sensations perceived on the tongue: sweet, sour, salty, bitter, umami.

- Aroma / Fragrance / Smell refers to volatile compounds detected by olfaction (nasal passages, retronasal olfaction).

- Flavor is the combined perception of taste + aroma + mouthfeel + smoke sensations.

Most of what makes a cigarette “taste” a certain way comes from aroma compounds and volatile flavors, more than from basic tastes.

Core Chemical Contributors to Tobacco Flavor

Tobacco flavor is derived from both intrinsic leaf compounds and added or modified compounds. Some of the key chemical classes and molecules include:

-

Volatile Aroma Compounds / Terpenes / Essential Oils

These compounds often come from the natural plant or from additives. Examples:

- Terpenoids, monoterpenes, sesquiterpenes

- Compounds like eugenol, camphor, menthol (in flavored tobacco)

- In flavored cigarettes, manufacturers quantify flavor compounds like eucalyptol, menthol, camphor, methyl salicylate, cinnamaldehyde, eugenol, coumarin, etc.

- Essential oils and esters also play a role in the “top-note” experience of flavoring.

-

Polyphenols, Chlorogenic Acids, Caffeic Acids

These phenolic compounds contribute to bitterness, astringency, color stability, and oxidative intermediates. Many degrade or transform during aging and heat.

-

Sugars, Carbohydrates & Maillard Reaction Products

Sugars (natural and added) are central to flavor development:

- They undergo Maillard reactions (reaction between reducing sugars and amino acids) during curing, aging, and heating, producing aromatic compounds such as pyrazines, furans, etc.

- Caramelization and sugar dehydration under heat also generate flavor volatiles.

- Some compounds like alkylpyrazines (formed via Maillard pathways) are particularly potent flavor molecules with low odor thresholds.

-

Amino Acids, Peptides & Amadori Compounds

Amino acids and peptides (e.g. tryptophan, asparagine) serve as precursors in Maillard reactions. Studies in cigar tobacco show that aroma precursors including amino acids, organic acids, sugar alcohols, and Amadori compounds correlate significantly with flavor traits (nutty, woody, fruity, roasted)

-

Organic Acids & Fatty Acids

Acids such as malonic acid, succinic acid, oleic acid, and linoleic acid are part of the aroma precursor pool. They can degrade or transform into further volatiles.

-

Alkaloids & Nitrogenous Compounds

Nicotine is the primary alkaloid, but there are also nornicotine, anabasine, myosmine, etc. While nicotine contributes largely to the “strength” and “bite,” interactions with flavor compounds matter.

-

“Characterizing Flavor” Additives

Beyond what is naturally present, manufacturers sometimes add casing agents, flavorings, top dressings — small quantities of volatile oils, esters, fruit extracts, menthol etc., to shape and enhance flavor.

Some studies identify 186 chemical compounds across flavored tobacco products, 144 of which were unique to flavored samples, categorized into flavor descriptors (fruit, menthol, floral, etc.).

Biochemical & Thermochemical Pathways in Flavor Development

To understand how flavor emerges, we need to look at the processes:

-

Precursor Formation in Leaf (During Growth & Maturation)

During plant growth:

- Biosynthesis leads to accumulation of sugars, amino acids, phenolics, carotenoids, terpenoids.

- Carotenoid degradation, lipid peroxidation, and glycoside hydrolysis generate aroma precursor molecules (e.g. C13 norisoprenoids) later released during aging or heating.

Example: In Nicotiana tabacum, carotenoid derivatives like megastigmatrienone are key aromatic precursors. Wikipedia

-

Curing & Aging Transformations

Once leaves are harvested and cured:

- Oxidation: Phenolics are oxidized, reducing harshness, creating aroma compounds.

- Chemical degradation / rearrangements: Especially in aging, slow reactions convert precursors into volatile compounds.

- Maillard reactions: Over longer times under moderate heat/humidity, reactions between sugars and amino acids yield flavor volatiles like pyrazines, furans.

- Volatilization / loss: Some volatile compounds evaporate during storage or handling, changing flavor balance.

-

Thermal Degradation / Pyrolysis During Smoking

When the cigarette is lit:

- High heat (~600–900 °C in the burning zone) causes pyrolysis and combustion of leaf matter.

- Precursor molecules break down or rearrange into gaseous or particulate volatile compounds (aldehydes, ketones, phenols, heterocyclics, furans, etc.).

- Many flavor compounds are derived from thermal breakdown of sugars, phenolics, carotenoids.

- Additive flavor compounds may volatilize or decompose to reinforce flavor perception.

Thus, the final flavor is an emergent property of all these layered processes.

Role of Curing, Aging & Processing

Flavor doesn’t just arise from chemistry—process control is critical.

Curing

- Types: air curing, flue curing, sun curing, fire curing, smoke curing depending on tobacco type.

- Temperature, humidity and airflow control during curing can accelerate or inhibit reactions. Over-drying or overheating can destroy volatile compounds.

Aging

- Time and conditions (temp, humidity, ventilation) determine conversion of precursors, reduction of harsh compounds, development of aroma depth.

- Controlled aging helps preserve volatile compounds and balance flavor.

Processing: Cutting, Conditioning, Casing & Flavoring

- Cutting / Shredding must be gentle to avoid mechanical damage or volatile loss.

- Conditioning: Adjusting moisture content before further processing.

- Casing: Application of aqueous solutions containing sugars, humectants, extracts. These modify flavor, mask harshness, and add body.

- Top-dressings / flavor sprays: Small, volatile flavor oils, esters, fruit or spice essences applied late in processing to finely tune aroma.

These steps must be precisely controlled to avoid destroying delicate volatiles or creating off-notes.

Influence of Machinery & Equipment on Flavor Quality

Machinery and processing equipment play a major role in preserving or altering flavor yield and consistency.

Equipment that Touches the Leaf

- Handling, conveying, and sorting machines must minimize mechanical stress that bruises surface or exposes leaf to oxidation.

- Proper airflow, temperature control in processing rooms reduces premature volatilization and degradation.

- Integration with Tobacco Machinery is key so upstream machines do not unduly damage leaf.

Processing / Flavoring Modules

- Casing machines and spray application systems need uniform distribution, atomization control to avoid hotspots or overspray.

- Dryers, conditioning chambers must control temperature and humidity to prevent volatile loss.

Downstream Machinery

- Cigarette Making Machines must maintain consistency in blend delivery, density, and packing so flavor perception is stable across sticks.

- Cigarette Filter Making Machines: filter materials and design influence how much flavor compounds reach the smoker (some filters absorb or alter volatiles).

- Spare Parts matter: worn parts, seals, gaskets, leaky ducts, or damaged surfaces can create local heating, friction, or leaks, which may degrade aroma compounds.

So meticulous maintenance, calibration, and design of machines are essential to retain flavor integrity.

Trade-offs, Challenges & Health Considerations

While the science behind flavor is fascinating, manufacturers must balance flavor goals with regulatory, health, and consistency constraints.

- Volatility vs Stability

Many flavorful compounds are volatile (e.g. small esters, aldehydes), which means they easily evaporate or degrade during aging/storage. Keeping a balance between preserving them and preventing off-smells is tricky.

- Health / Toxicity Concerns

Some flavoring agents or their combustion by-products may be harmful:

- Flavoring chemicals (e.g. diacetyl, aldehydes) have raised health concerns in inhalation exposures.

- Research shows certain vanilla or clove flavoring agents may cause vascular cell damage in vitro.

- Some flavor additives are converted to carcinogens or toxic compounds under combustion (e.g. heated sugars generate furans, aldehydes).

Thus, flavor development must be safe, regulated, and consistent.

- Regulatory Limits

Many jurisdictions restrict or ban “characterizing flavors” that make cigarettes more appealing, especially to youth.

Manufacturers must ensure flavor additions are compliant, and that flavor perception does not cross into banned territory.

- Batch-to-Batch Consistency

With natural variability in leaf chemistry, processing, and additive performance, maintaining consistent flavor across production lots is challenging.

- Cost & Technical Complexity

High-precision flavoring, volatile preservation equipment, advanced machinery, and R&D for flavor are expensive

Integration with the Production Chain & Brand Strategy

All the above science must align with manufacturing, quality control, and brand identity.

- Your flavor strategy must work with your other machinery and systems (Tobacco Machinery, production lines, filter and packing).

- A brand’s flavor signature (e.g. “smooth, aromatic, spicy”) must be reproducible, which demands control at every stage. In markets like Cigarette Brands Dubai, flavor consistency is key to brand loyalty.

- Flavor choices must balance consumer preferences, cost, regulatory risk, and health compliance.

Emerging Trends & Future Directions in Tobacco Flavor Science

The field continues to evolve. Some promising directions:

- Machine Learning / AI in Flavor Prediction

Use of AI to predict which flavor molecules will emerge from given leaf + processing parameters.

- New Natural Flavor Molecules Discovery

Frameworks are emerging to design and optimize natural flavor molecules for stability and flavor complexity.

- Better Traceability of Precursors

Genomic and metabolomic profiling of leaves to predict flavor potential before processing.

- Controlled Micro-Environments for Aging

More precise microclimate control in aging warehouses to tune flavor development.

- Lower Temperature Processing / Gentle Methods

To preserve delicate volatiles, milder temperature regimes in conditioning, casing, drying.

- Sustainable / Biodegradable Filters & Additives

New filter materials or additive carriers that do not absorb or strip aroma compounds.

- Flavor Modulation via Microencapsulation

Encapsulated flavor compounds that release under specific temperature or humidity triggers.

Q: Are all flavor compounds in tobacco added artificially?

No — many flavor compounds come naturally from the leaf (terpenes, carotenoid derivatives, phenolics, sugars). Additives are used to enhance, mask, or refine flavor.

Q: Can we taste the same flavor each time precisely?

It’s difficult — natural variability in leaf chemistry, processing shifts, volatility loss make perfect consistency a challenge. Tight process control is needed.

Q: Do filters affect flavor perception?

Yes — filters may absorb or alter volatile compounds. Filter design (material, porosity) influences how much aroma reaches the smoker.

Q: Is it safe to add flavor chemicals?

Flavor additions must comply with regulatory limits and safety testing. Some compounds become harmful under combustion, so R&D and safety evaluation are essential.

Conclusion

The science behind tobacco flavor development is a rich blend of plant biochemistry, processing engineering, thermochemistry, and sensory science.

From the molecules formed in leaf during growth, to the transformations in curing/aging, to thermal breakdown during smoking — every step contributes to the final aroma, taste, and “feel” of a cigarette. Additives and flavoring strategies provide fine tuning, but must cohere with safety, regulation, consistency, and manufacturing constraints.

For your production ecosystem, integrating this flavor science with well-maintained machinery (from upstream Tobacco Machinery to Cigarette Making Machines, Cigarette Filter Making Machines and a solid spare-parts regime) is crucial. That’s how a brand can reliably deliver its signature flavor, retain consumer loyalty, and operate effectively in competitive markets, including in Cigarette Brands Dubai.