Advanced Cigarette Making Solutions by Orchid Tobacco Dubai

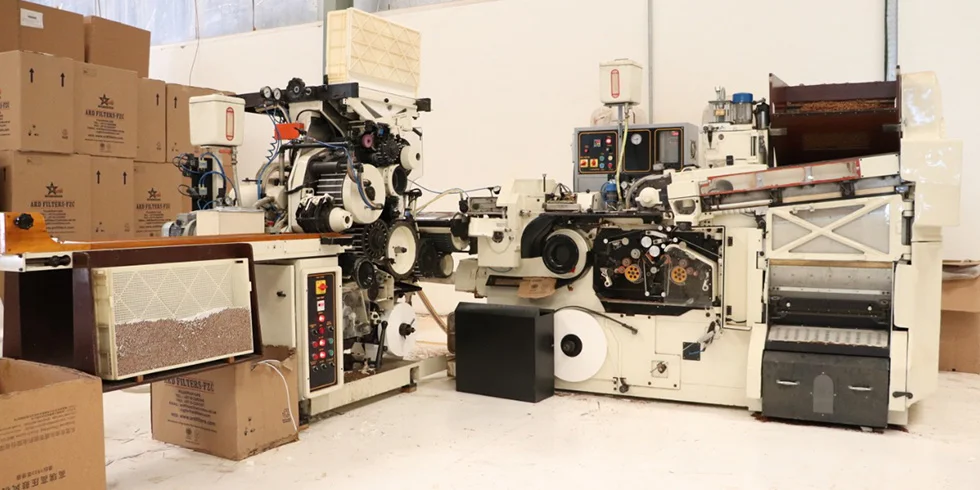

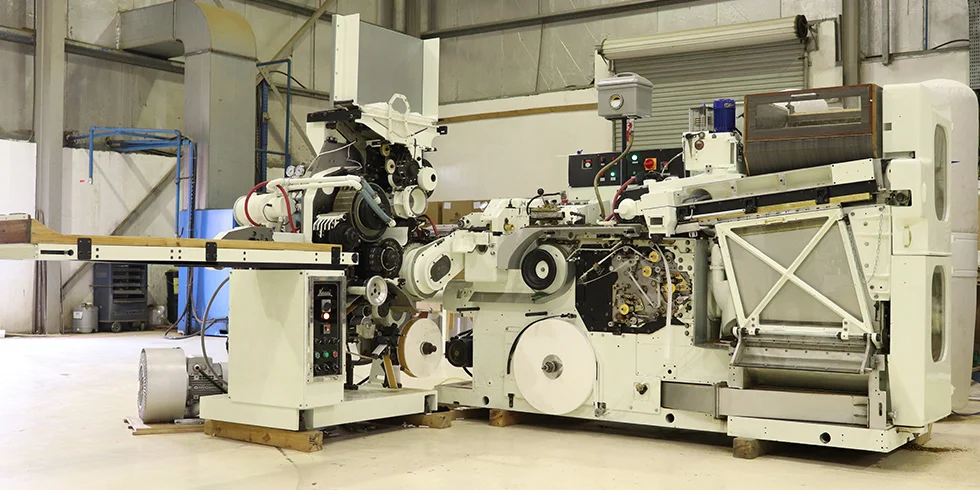

At Orchid Tobacco Dubai, we specialize in the development and supply of high-performance Cigarette Manufacturing Machines designed to meet the evolving needs of the global tobacco industry. Our automatic cigarette making machines combine precision engineering with modern automation to ensure consistency, efficiency, and superior product quality.

Each Cigarette Manufacturing Machine is built for durability and high-speed operation, featuring advanced systems for rod formation, filter attachment, cutting, and wrapping. Whether you require machines for king size, slim, super slim, or nano cigarettes, Orchid Tobacco delivers customized production solutions to match your capacity and format requirements.

Explore Our Range of Cigarette Manufacturing Machines

Cigarette manufacturing is a highly automated and precision-driven process that depends on cutting-edge equipment to maintain uniformity and performance. At Orchid Tobacco, we provide a complete range of Cigarette Making Machines suitable for both new factories and expanding production lines.

Our cigarette production systems integrate with other essential tobacco machinery to create seamless, end-to-end production setups that meet international manufacturing standards.

What Are Cigarette Manufacturing Machines?

Cigarette Manufacturing Machines are specialized industrial systems used for large-scale production of cigarettes. They automate key stages such as tobacco feeding, rod making, filter assembly, wrapping, and cutting — resulting in high-speed, uniform output with minimal waste.

By using these machines, manufacturers can maintain consistent cigarette quality while reducing labor costs and production time.

Main Components of Cigarette Making Equipment

1. Rod Making Units

These form the core of the manufacturing line. Tobacco is combined with rolling paper to produce a continuous cigarette rod, which is then cut into individual sticks. High-precision rollers ensure consistency in density and length.

2. Filter Assembly Units

These machines attach filters to the cigarette rods, ensuring perfect alignment and secure bonding for an even smoking experience.

3. Cutting Units

Once the rods and filters are joined, high-speed rotary cutters slice the rods into standard-size cigarettes with clean, precise edges.

4. Wrapping Units

Wrapping machines use tipping paper to enclose the cigarette, improving appearance and maintaining hygiene.

5. Inspection and Quality Control Systems

Modern cigarette production lines are equipped with sensors and inspection units that detect and remove defective products before packaging.