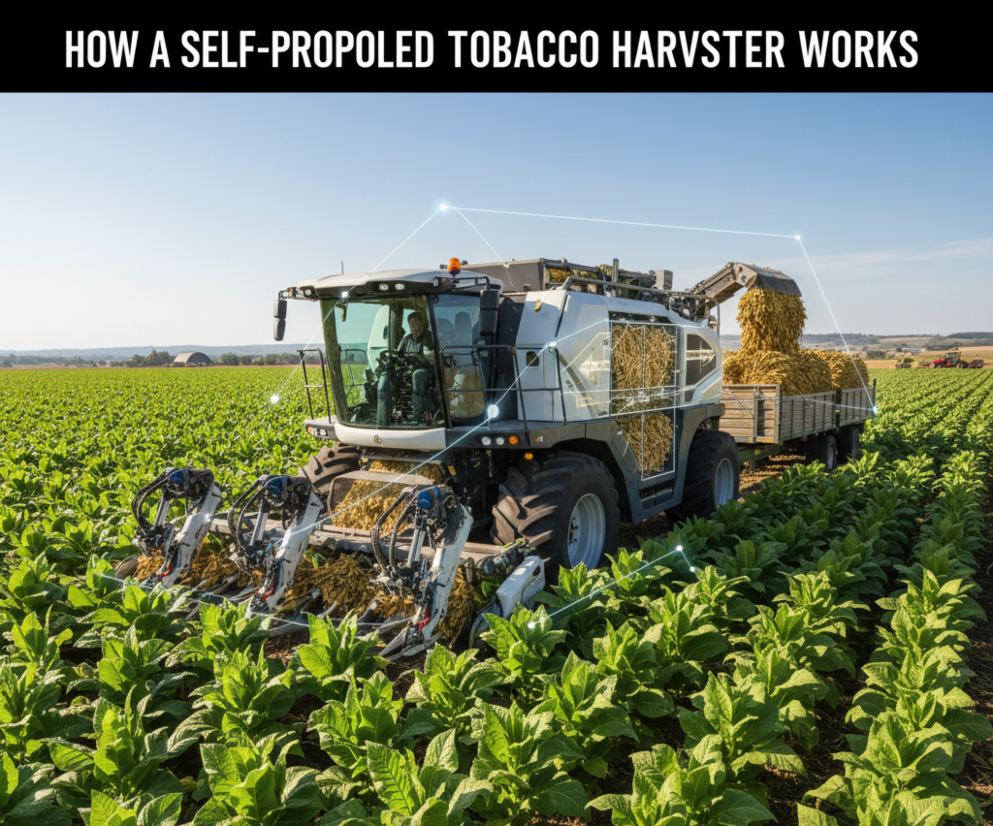

Tobacco farming is one of the most labour-intensive agricultural activities, particularly at harvest time. A self-propelled tobacco harvester is designed to revolutionize this stage of the process, making harvesting faster, easier, and more efficient. Unlike traditional harvesting methods that rely heavily on manual labour or tractor-pulled machinery, a self-propelled harvester is a single unit that drives itself and harvests tobacco leaves with precision.

In this complete guide, we’ll explore:

By the end, you’ll have a clear understanding of why these machines are a game-changer in the tobacco industry.

A self-propelled tobacco harvester is a machine that combines mobility and harvesting functions in one unit. Instead of being pulled by a tractor, it has its own engine, wheels or tracks, and operator controls. As it moves through rows of tobacco plants, it automatically removes leaves from the stalk, transports them via conveyors, and stores them safely onboard until unloading.

The main purpose of such harvesters is to reduce manual effort, speed up harvesting operations, and ensure consistent leaf quality throughout the process.

The operation of a self-propelled harvester involves several stages:

Different farm sizes and tobacco varieties require different types of machines.

Investing in a self-propelled harvester brings significant benefits:

Challenges & Considerations

Despite the benefits, there are challenges to consider:

Farmers should weigh these factors carefully before purchasing.

When selecting a model, consider:

Harvesting is only the first stage of the tobacco journey. After leaves are harvested and cured, they move downstream into processing, cigarette making, and packing.

At Tobacco Machinery, you’ll find the complete ecosystem of machines that work together with harvesters.

For example:

On the consumer side, global demand continues to evolve, as seen in our Cigarette Brands Dubai insights. Better harvesting upstream leads to better product quality downstream.

The cost of these machines can be high, but the return on investment often justifies it.

When maintained properly, these machines can last for many years, delivering consistent performance.

Practical Applications & Use Cases

Self-propelled tobacco harvesters are ideal for:

| Factor | Manual Harvesting | Tractor-Pulled Machines | Self-Propelled Harvester |

| Labour | High | Moderate | Low |

| Speed | Slow | Medium | High |

| Cost | Low upfront | Medium | High upfront, lower long-term |

| Leaf Quality | Depends on workers | Moderate | Consistently high |

| Best For | Small farms | Mid-sized farms | Large, commercial farms |

Not entirely. Operators and workers are still required for curing, sorting, and logistics.

For large farms, yes. They quickly pay back through efficiency and reduced labour.

Most models are adjustable, but always check compatibility with your variety.

A self-propelled tobacco harvester is more than just a machine — it’s a major step forward in modernizing tobacco farming. By reducing manual labour, improving efficiency, and ensuring consistent quality, it integrates seamlessly into the larger production cycle that includes processing, cigarette making, and packing.

When combined with advanced solutions like Cigarette Making Machines and packing lines such as the HLP-2 Packing Line 180 Cigarettes Packer, farmers and manufacturers can achieve end-to-end efficiency from field to finished product.

We specialize in the provision of Tobacco Machinery. Our expertise encompasses not only the trading of machinery but also extends to being a dedicated supplier. This specialization is enriched by our comprehensive solutions tailored for emerging Cigarette Companies. What sets us apart is our ability to offer firsthand insights through our active Cigarette Manufacturing operation in the UAE.