In high-speed cigarette manufacturing, efficiency, precision, and output capacity are critical factors. The ability to produce high volumes of cigarettes while maintaining consistency in quality and minimizing waste is essential for manufacturers. Two of the leading machines in this sector, the Protos 70 and Protos 80ER, offer advanced capabilities tailored for various production needs. While both machines share many similarities in their specifications, key differences in production speed and efficiency make them suited for different operational requirements. This document explores the advantages of the Protos 70 compared to the Protos 80ER and provides insights into their suitability for different production environments. (Explore Our Tobacco Machinery)

One of the primary factors to consider when selecting a cigarette manufacturing machine is its production capacity.

The specifications of the cigarettes that a machine can produce play a crucial role in determining its flexibility for different market demands.

Automation and precision in manufacturing are ensured through advanced control and weight monitoring systems.

Both machines share the same fundamental unit configurations, affecting their functionality and operational setup.

Energy efficiency is an important consideration, especially for high-speed manufacturing.

When evaluating the Protos 70 and Protos 80ER, the Protos 80ER holds a clear advantage in terms of higher production speed, making it the better choice for large-scale, high-speed manufacturing facilities. The ability to produce 1,000 more cigarettes per minute compared to the Protos 70 can result in significantly increased output over time, improving production efficiency and overall profitability.

However, if a manufacturer does not require speeds beyond 7,000 cpm for regular diameter cigarettes, the Protos 70 remains a viable option. With identical energy consumption, cigarette specifications, machine configurations, and automation features, the Protos 70 offers the same quality, flexibility, and efficiency at potentially lower initial investment costs.

For businesses focusing on maximum throughput and high-speed manufacturing, the Protos 80ER is the preferred model. However, for operations where 7,000 cpm is sufficient, the Protos 70 provides an equally efficient solution without compromising on quality or operational efficiency. Choosing between the two ultimately depends on specific production goals and volume requirements.

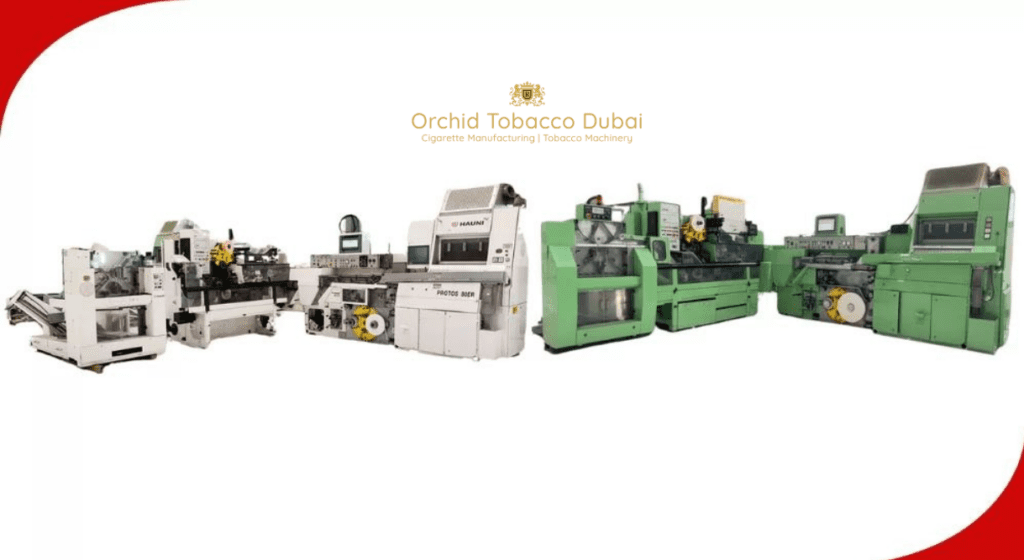

Orchid Tobacco is a leading provider of high-quality tobacco machinery, Cigarette manufacturing machines and Tobacco Machinery spare parts serving businesses across the US, Canada, Europe, Russia, and Poland etc. We specialize in supplying state-of-the-art manufacturing, packing, and processing equipment designed to enhance efficiency, precision, and productivity in the tobacco industry. With a commitment to innovation and excellence, we offer reliable solutions tailored to meet the diverse needs of cigarette manufacturers worldwide.

We specialize in the provision of Tobacco Machinery. Our expertise encompasses not only the trading of machinery but also extends to being a dedicated supplier. This specialization is enriched by our comprehensive solutions tailored for emerging Cigarette Companies. What sets us apart is our ability to offer firsthand insights through our active Cigarette Manufacturing operation in the UAE.